Rollomatic solutions in automotive and electric vehicles provide generational longevity for the life cycles of automotive programs and quality tool making from aluminum to complex composites.

Rollomatic has been serving the automotive manufacturing industry even back in the 1980s. And now we serve the electrical vehicle manufacturing sector as well. With long term key customers in the automotive space, Rollomatic knows the challenges our customers face in serving Tier 1 manufacturers and OEMs.

Our customers in automotive and EV work with standard materials such as steel, but have tight tolerances when it comes to manufacturing products like engines and transmissions. The key is consistency, and that’s what Rollomatic does very well. Automotive suppliers may get a contract to make cutting tools on a program that will last many years. Rollomatic is with our customers every step of the way, and we make machines that will outlast the life of the automotive programs our customers are awarded.

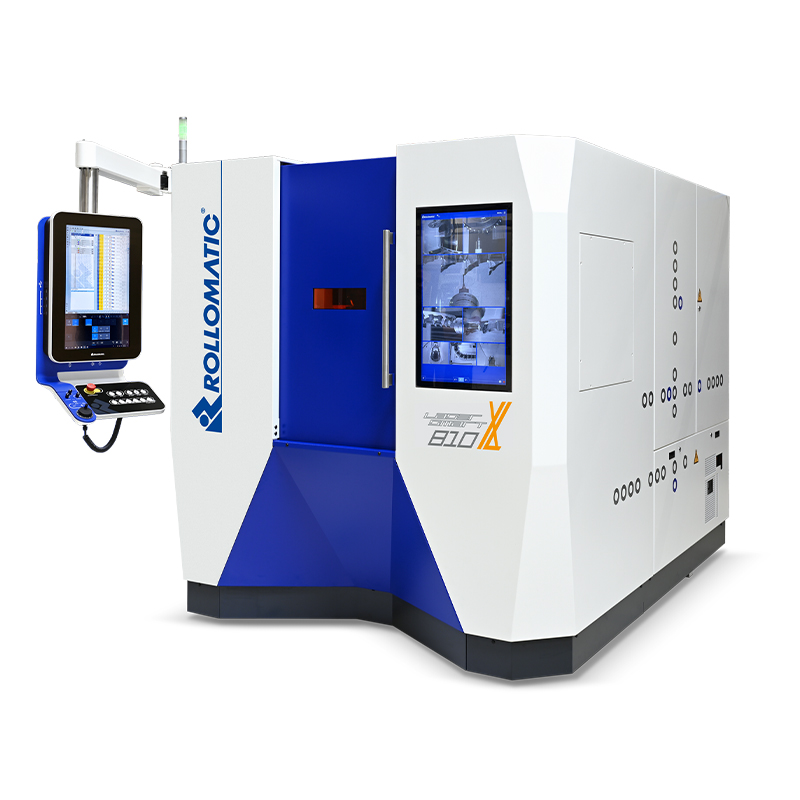

The Solutions that Rollomatic provides in the automotive and EV manufacturing space are often the GrindSmart® 630XW, GrindSmart® 660XW, GrindSmart® 830XW, GrindSmart® NP30, and the LaserSmart series. With more engine blocks being made of aluminum, those need the diamond tools and ultra hard materials that our LaserSmart series specializes in. The 6-axis technology in Rollomatic solutions allows for the tight tolerances and tighter requirements the automotive and EV sectors need. Automotive customers benefit from operator training in the Rollomatic Learning Center, and face-to-face training and support. Our industry leading Smart Autonomous Grinding helps suppliers set up for the long term with great efficiencies in manufacturing. For more information on our solutions, click the machines below.