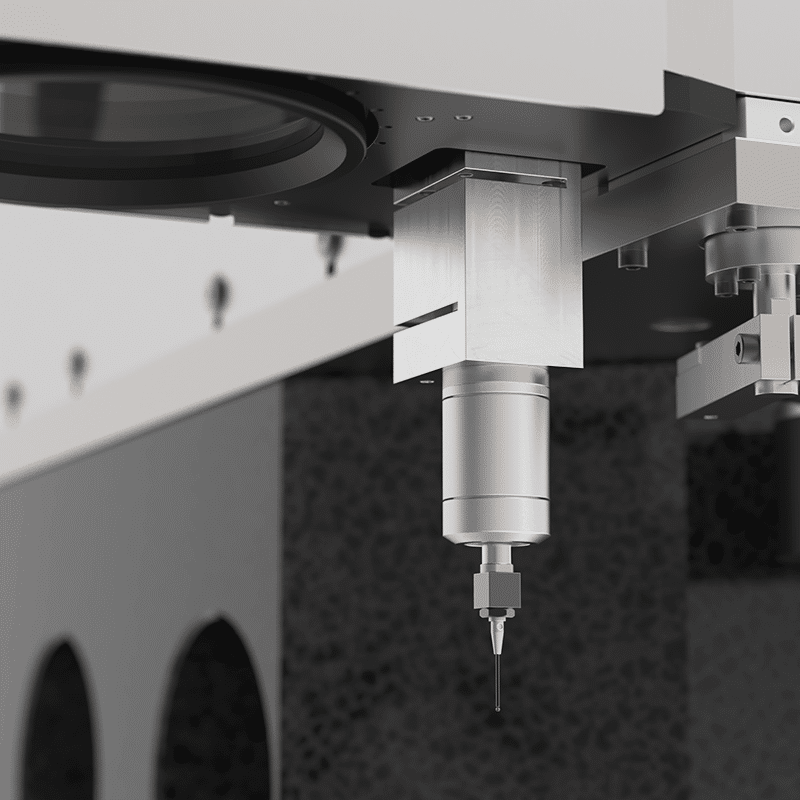

The new LaserSmart 510 has been designed to allow for faster cutting speeds of up to 450% over conventional laser machining. The laser machining process used on this machine is infinitely superior to any other traditional method of machining super-hard materials such as PCD, CVD diamond, monocrystalline diamond, natural diamond and PCBN.