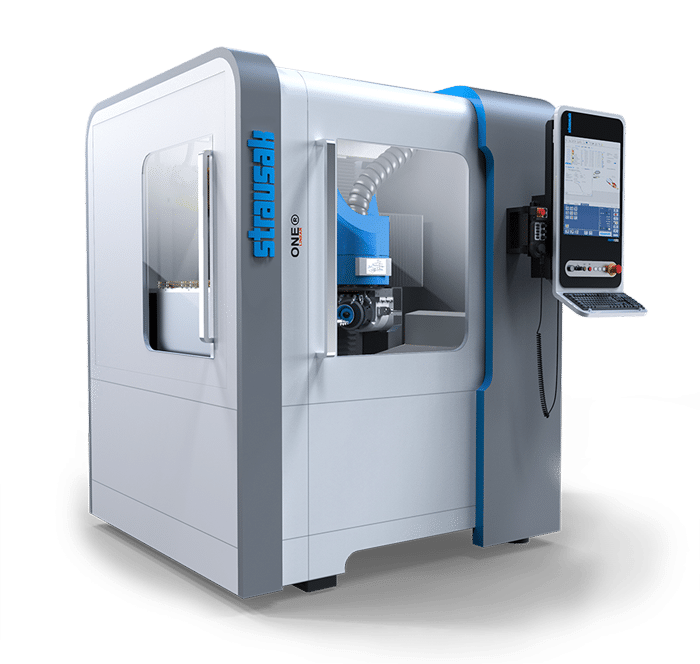

Strausak

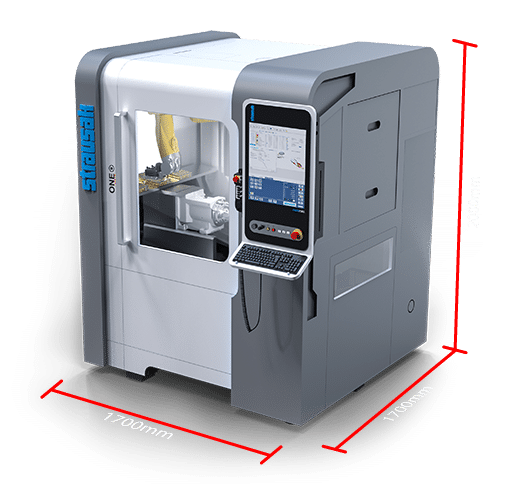

Strausak was acquired by Rollomatic in 2011 to address the “job shop tool grinding” industry. With the latest generation, Strausak ONE linear, we address the high mix / low volume, and resharpening needs of our customers. The Strausak ONE has been designed to allow for efficient set up time and ease of operator use, which is further facilitated by the use of Numroto.