Rollomatic serves the Aerospace industry with solutions capable of Complexity geometry, tight tolerances, with software to match the complexity of the tools.

Rollomatic is privileged to serve the Aerospace industry with industry leading expertise in the types of cutting tools needed. Some of the challenges in Aerospace cutting tools are the complex geometries, hard materials, and multiple types of materials used. In addition, the materials used are often high cost materials, so efficient and precision cutting is critical.

From materials such as high nickel, inconel (nickel-chrome based superalloys), aluminum, and carbon fiber, surface finish is extremely important. Rollomatic understands that the right tool for the job in aerospace has to be geared for the job, or else manufacturers go through tools quickly, and can risk scrapping expensive materials because the tools were not sharp enough. The Aerospace industry also has complex tools, not just a 4-flute standard end mill to cut steel, but odd numbered 5-11 flute, variable helix, uneven index type tools that are produced to withstand the material being machines.

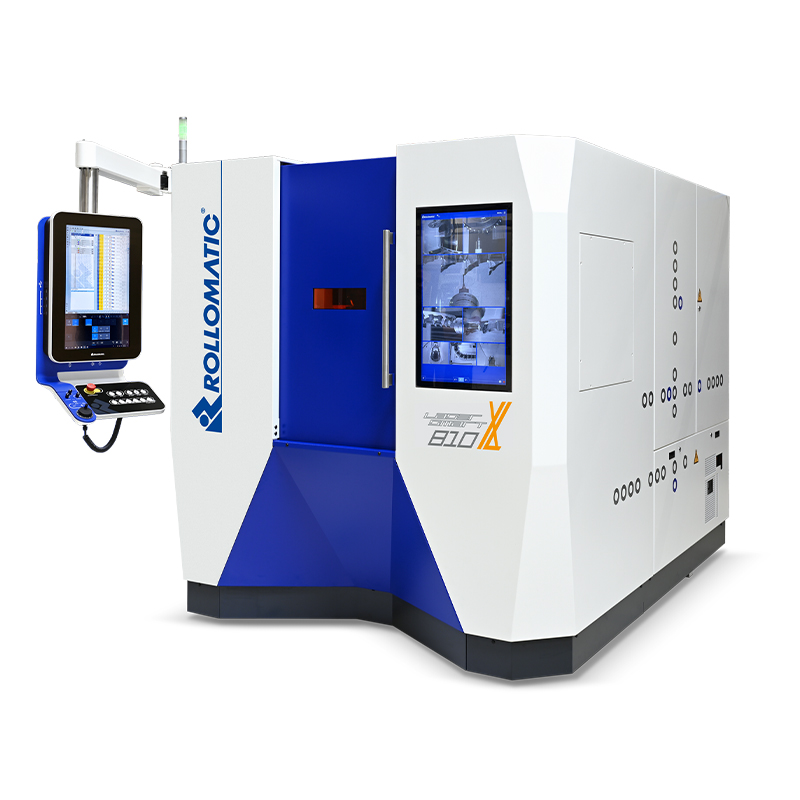

The Rollomatic GrindSmart® 830XW, and the GrindSmart® 630XW are the most common machines in aerospace along with the ShapeSmart® machines for step tools for drilling and reaming tools. The GrindSmart® 830XW is also great for larger diameter tools, complimented by its 6-axis technology with new innovative capabilities. Rollomatic’s VirtualGrindPro software comes with templates for the operators ready to go. Rollomatic provides face-to-face training and support along with the Rollomatic Learning Center for customer success. We understand the complexities and challenges of making tools for the aerospace industry, and our engineering teams continue to innovate with our customers leading in the industry. For materials requiring PCD cutters, Rollomatic have designed a 6 axis laser machines, the LaserSmart 810XL will tackle all challenges in machining ultra-hard cutting tools machine tools with a diameter of up to 300mm and an OAL of 350mm. Click the machines below for more information. If you would like to pursue a no charge pre-sales test grind, cycle time, or feasibility study, or a demo please reach out.