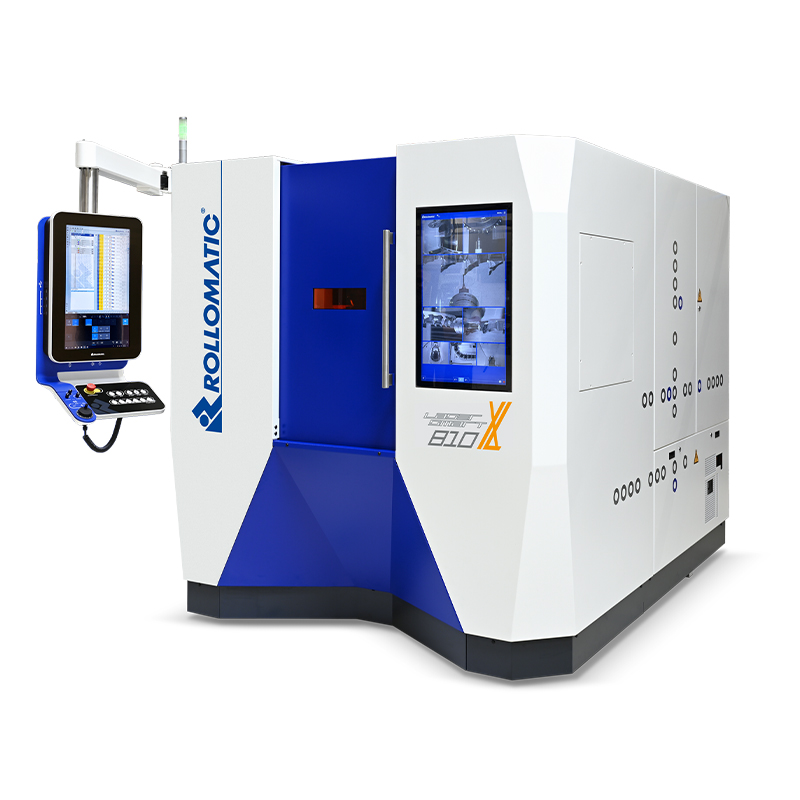

Rollomatic maintains a leadership position in the field of laser cutting ultra-hard materials with innovative and powerful femto-second lasers, never seen before in the cutting tool industry. The Rollomatic LaserSmart® series has unlimited machining capabilities of ultra-hard materials such as PCD, CVD diamond, monocrystalline diamond, natural diamond and PCBN.

The machines provide super fine surface finishes, crisper and sharper cutting edges, 3D machining, profile cutting, cylindrical margins, chip breakers, fluting and more. Our revolutionary process allows users to achieve the results that set new standards in ultra-hard material machining.

Rollomatic maintains a leadership position in the field of laser cutting ultra-hard materials with innovative and powerful femto-second lasers. The Rollomatic LaserSmart® series has unlimited machining capabilities of ultra-hard materials such as PCD, CVD diamond, monocrystalline diamond, natural diamond and PCBN.

This revolutionary process allows users to achieve the results that set new standards in ultra-hard material machining.

This new LaserSmart® model is the world’s only femto-second laser cutting machine for PCD and other ultra-hard materials.

- Never seen before in the cutting tool industry.

- super fine surface finishes, crisper and sharper cutting edges Specifically improves finishes on 3D machining of drills and endmills.

- 30% faster feedrates compared to conventional laser machines.

- The pulse width on a femto-second laser is 1,000 times faster than a pico lasers.

- 3D machining, profile cutting, cylindrical margins, chip breakers, fluting and more.

- Also suitable for ceramics, carbide, sapphire, glass or other ultra-hard materials.

- The machine adapts the machining process automatically to the type of material.

These revolutionary machine processes allow our customers to achieve the results that set the new standard in ultra-hard material machining. Can produce complete tools, including cylindrical margins and chip breakers, in one single clamping.