The 5-axis grinding center, GrindSmart®Nano5, has been designed to manufacture medical, dental and industrial cutting tools with diameters as large as 6.35 mm (.25″) in HSS, stainless steel or carbide material.

The 5-axis grinding center, GrindSmart®Nano5, has been designed to manufacture medical, dental and industrial cutting tools with diameters as large as 6.35 mm (.25″) in HSS, stainless steel or carbide material.

Our vision of “Smart Autonomous Grinding” is to provide Rollomatic machine users with a fully autonomous machine capable of managing the production by itself with very little human intervention. A part of this ambitious project is the ability of the machine to manage the offsets to get the first parts within specification. Further items include to be able to achieve unattended production over several days within very tight tolerances an to interact with external robotic and automation systems. The Smart Autonomous Grinding program also includes machine connectivity and communication exchange systems with other equipment such as measuring machines, laser etching, etc.

The high-speed tool loader, designed by Rollomatic and integrated into the basic machine, was developed with fast setup and ease-of-use in mind. This is

achieved by using pre-calibrated cassettes and clamps to hold different

diameters without resetting the position. Rollomatic automatic loaders are known to be the fastest and most reliable in our industry.

• Fast to set up

• Capacity up to 1’360 parts

• Robust, low maintenance design

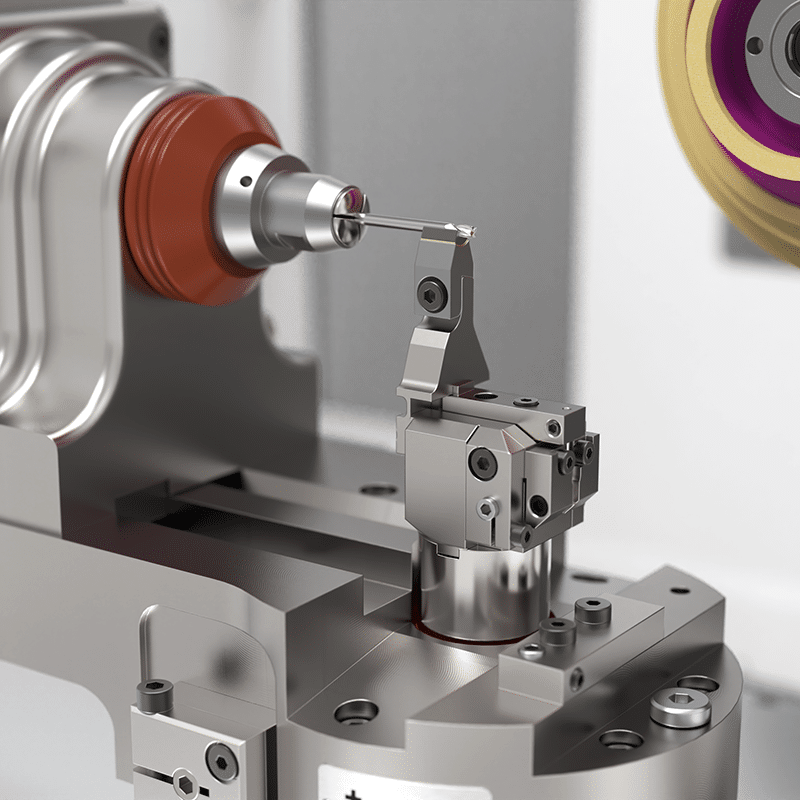

The Smart Shank Guide is a tool shank guiding system that guarantees

concentricity down to a few microns at each clamping. It saves time and boosts

productivity, as it is no longer necessary to probe for runout during setup.

• Exceptional concentricity accuracy, less than 0.002 mm at each clamping

• Quick and easy to set up

• Increased productivity

The Smart Steady Rest is a high precision steady rest for drills and other long tool blank. It provides stability in the grinding process and allows for faster feedrates.

This ensures repetitive quality of the tool throughout the production process.

• Quick and easy to set up

• Highly accurate adjustment system in 3 planes

• Consistent production quality

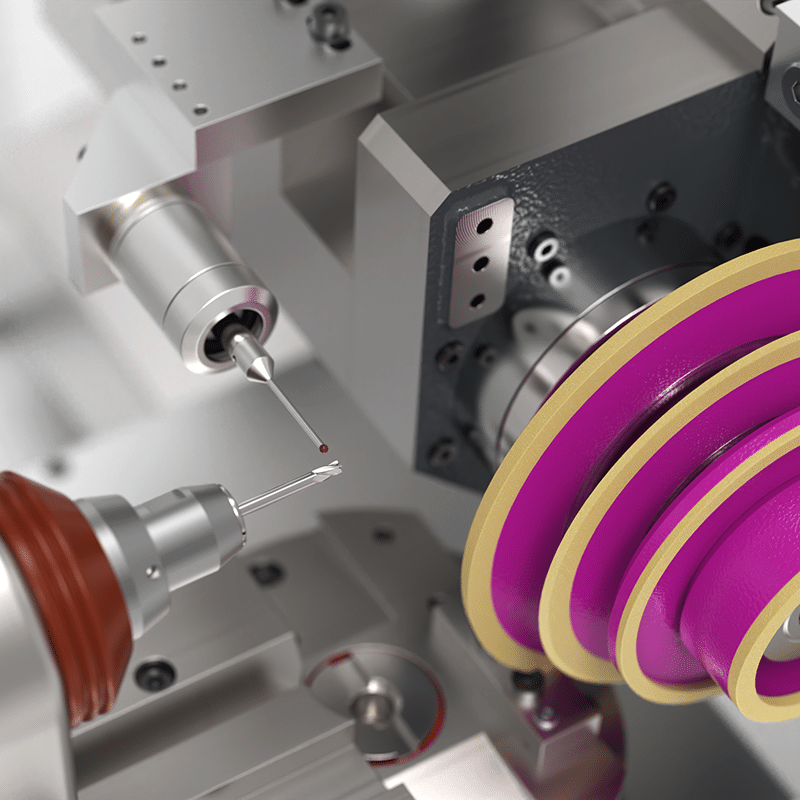

The Smart Touch Probe is a contact measurement system that allows the blank

position to be defined before grinding and avoids variations during production.

The system also compensates for machine thermal drift caused by changes in

ambient temperature and for wheel wear.

• Runout compensation and core diameter measurement

• Setting assistance

• Superior stability during the production process

• Elimination of scrap during unattended production

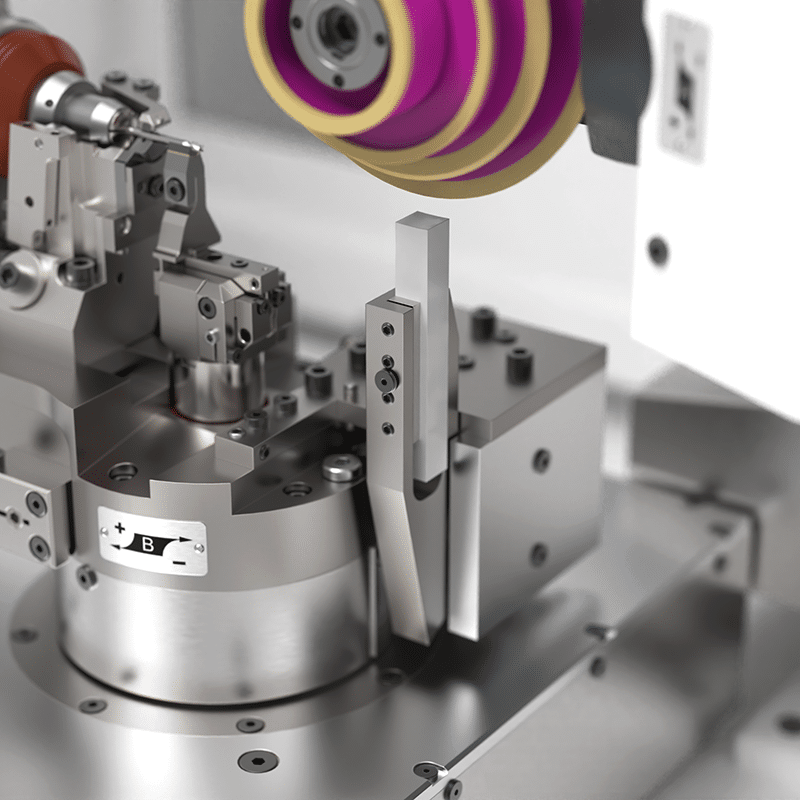

The StickSmart® is an automatic sticking system for in-process cleaning of

grinding wheels. The «stick», mounted in a holder, is used to regenerate superabrasive grinding wheels to maintain their cutting performance.

• Extends the working life of the wheel

• Extends unattended production cycles with high-performance wheels

• Reliable and safe automatic process for the operator

• Efficient, economical and safe solution

VirtualGrind®Pro is the innovative and powerful programming software that

comes with Rollomatic GrindSmart® CNC grinding machines. VirtualGrind®Pro is

intuitive, modern, easy to use and flexible. Its perfect combination with

Rollomatic precision machines gives the user the ability to program and grind

any type of cutting tool, standard or complex.

Industry 4.0 is a constantly evolving world, and management tools have been

developed to optimise its productivity. Rollomatic strives to develop connectivity solutions that are facilitating connections between peripherals in production processes and leveraging the available data.

Smart conectivity