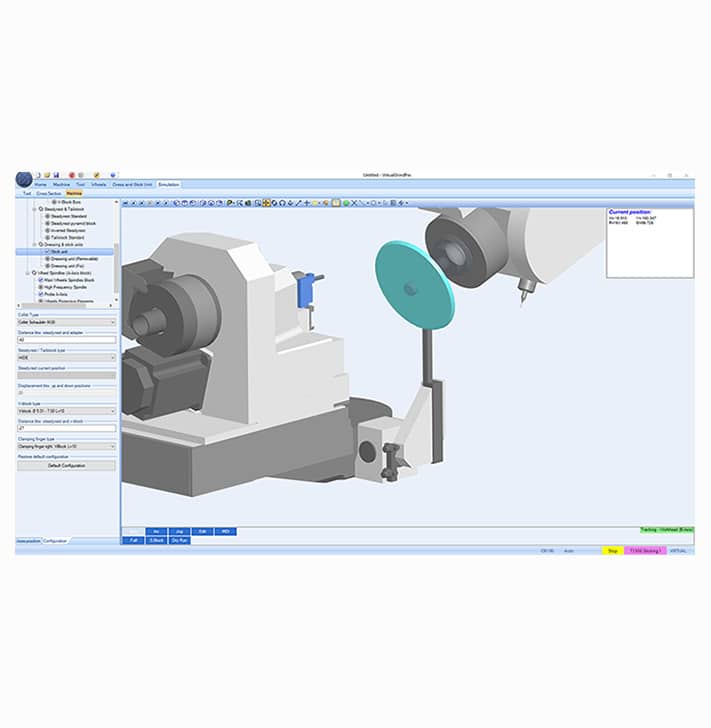

VirtualGrind®Pro is the innovative and powerful programming software that comes with Rollomatic GrindSmart® 5- and 6-axis CNC grinding machines.

VirtualGrind®Pro is the innovative and powerful programming software that comes with Rollomatic GrindSmart® 5- and 6-axis CNC grinding machines.

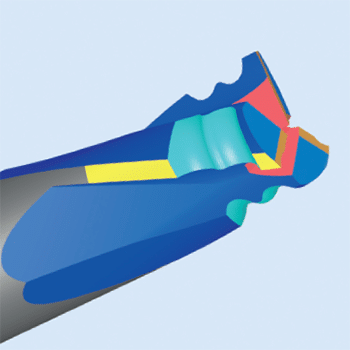

Designed by our own team of engineers to meet all the requirements of our customers, this software is the result of 30 years’ experience in precision cutting tool grinding.

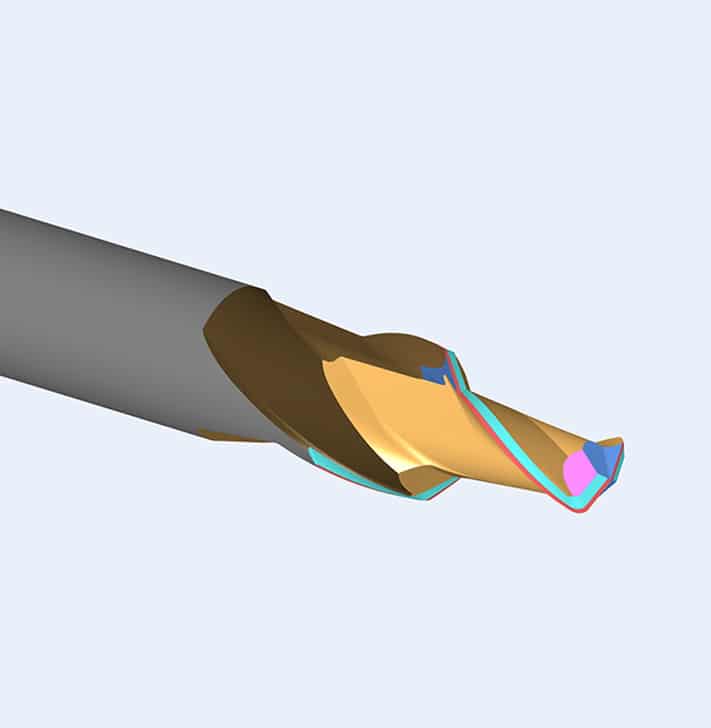

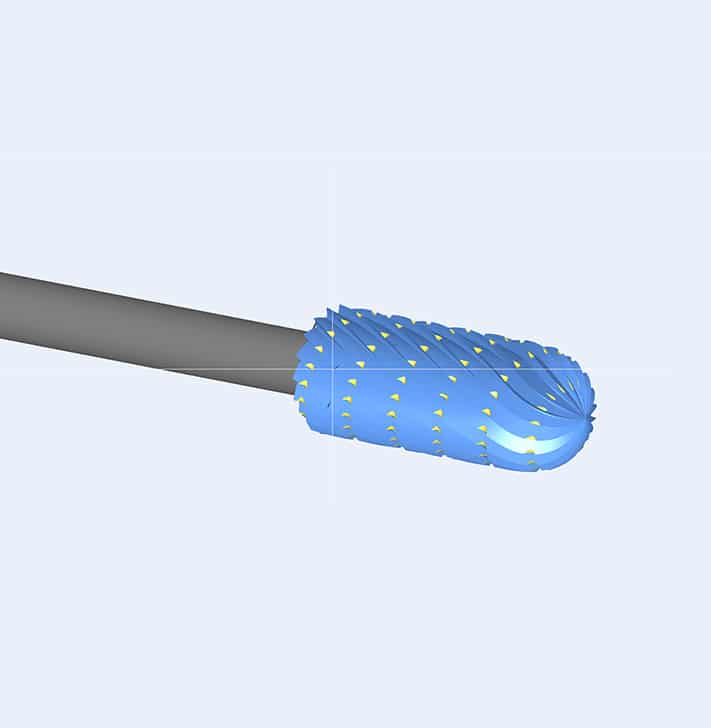

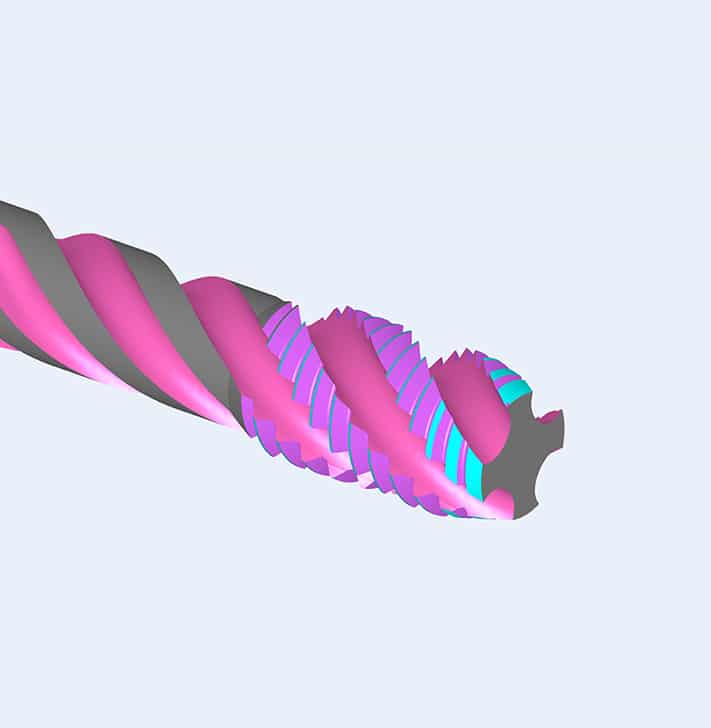

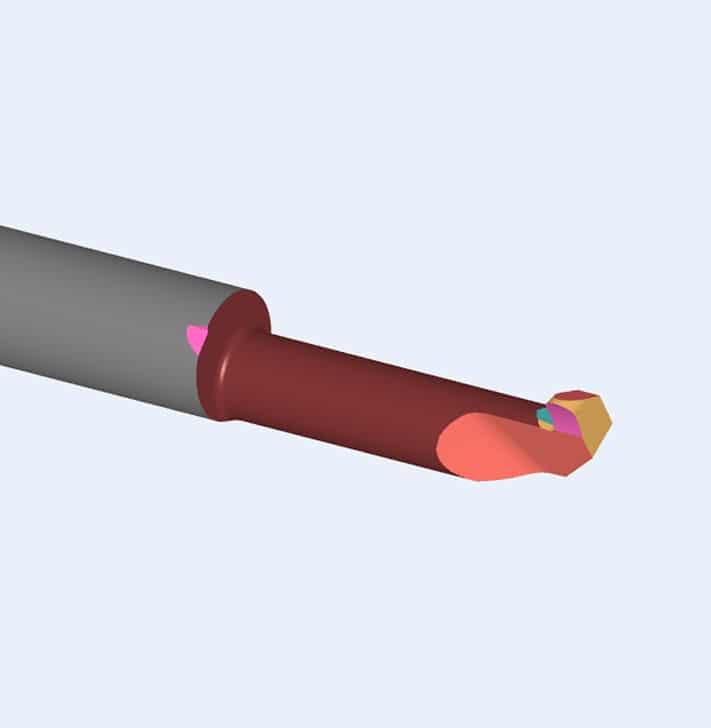

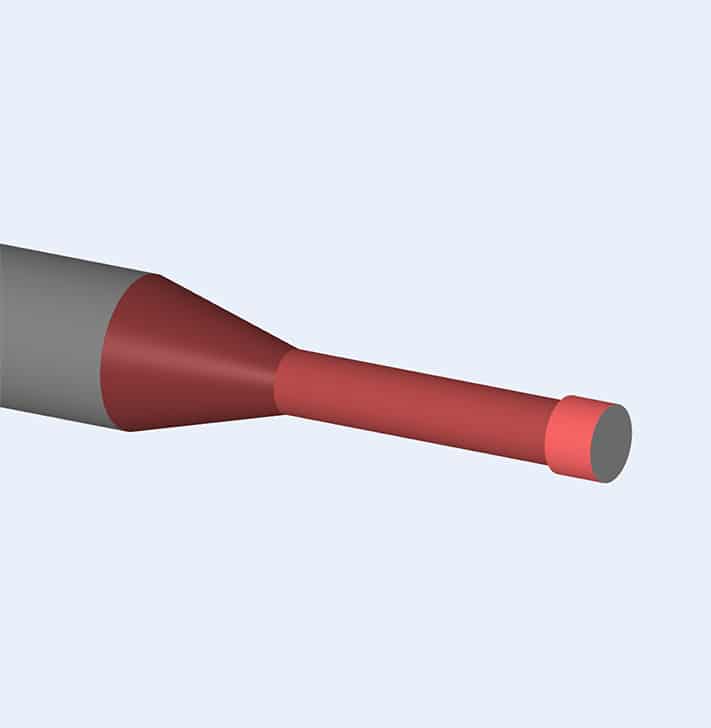

VirtualGrind®Pro is intuitive, modern, user-friendly and flexible. A perfect combination with Rollomatic precision grinding machines, the user can program and grind all types of high-performance standard or special cutting tools.

ADVANTAGES

- All Rollomatic grinding machines come with the complete VirtualGrind®Pro tool package. No additional software options need to be purchased at a later date.

- Rollomatic customers benefit from free software updates throughout the machine’s lifespan.

- The VirtualGrind®Pro has all the necessary functionalities to set up autonomous production.

- A unified interface for the whole Rollomatic ecosystem facilitates the learning curve and communication between the tool designer, production engineer and machine operator.

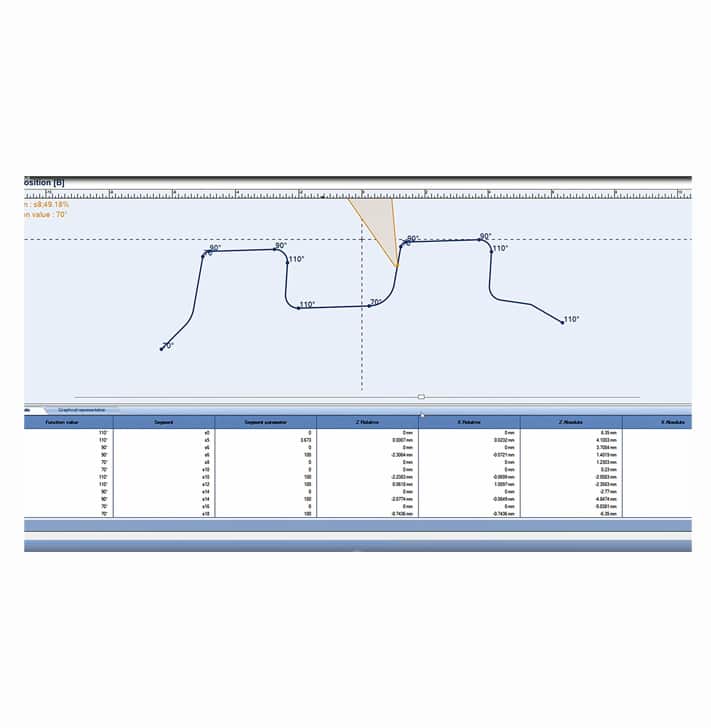

- Unparalleled programming flexibility with all accessible parameters.

- Machines and software are created and maintained by Rollomatic for unparalleled efficiency.