Automation solves a variety of challenges: are you struggling to find skilled employees? Do you have high precision, complex parts that require reduction of human error? Is adding an unattended shift crucial to your continued growth?

From simple, standard automation to the SmartFactory of the future, Rollomatic is your long term partner in the journey of Automation. For over 30 years Rollomatic has incorporated loading systems as standard into our machines. Today, we continue to provide automation solutions from simple loading systems to Humanoid robots. Here are some of the solutions we offer:

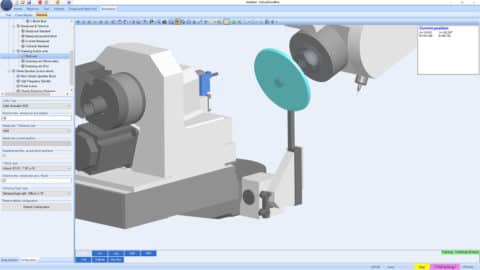

Wheel Changer

The integrated wheel changer (available on the GrindSmart 530XW, 630XW, 660XW, and 830XW) is a simple but effective means of automation. With up to 16 wheel packs available on the 830XW and 630XW3, customers can utilize the Rollomatic JobManager function to produce several different cutting tools with no operator intervention.

Standard Tool Probe (GrindSmart)

To reference the end position of the tool, for probing runout to be able to compensate for variations in runout, probing of blank and finish diameter, probing flute core, probing for coolant holes, flats on parts to orient grinding, probe for grooves.

ShapeSmart Length Probe

Sets the front reference position automatically.

Blum Laser Probe

A non-contact precision measuring option that can verify the diameter,radii, index, TIR, measuring corner & ball nose radii for in process compensation.

StickSmart

The StickSmart system automatically cleans up the grinding wheels during the grinding process to ensure that abrasive wheels have the same performance for short and long batches

ShapeSmart AutoSticking

Automatically applies a stick stone to the finish grinding wheel. Allows for longer unattended grinding on the ShapeSmart series.

On Board Wheel Dressing

A feature offered in the GrindSmart series allows for the dressing of grinding wheels inside of the machine. Flats, angles, and even shapes are achievable.

Standard Loader (GrindSmart/ShapeSmart)

810XL Loader

Gantry loader with carousel style parts queue capable of loading up to 33 lbs parts.

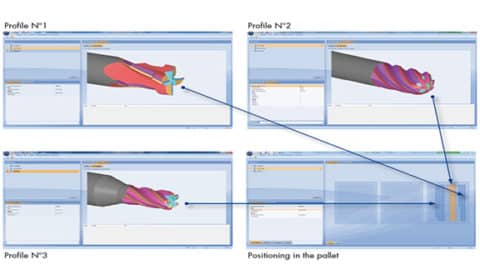

Job Manager

With the Job Manager feature, included as standard in VirtualGrind®Pro software, the user can produce series of tools with different geometries from a blank with the same diameter for unattended production.

Fanuc Robot (830XW/LaserSmart)

For larger tools, Rollomatic has incorporated the Fanuc six axis robot into several models of machines. This allows for larger & heavier tools to be accommodated.

Special Loader Applications (Bowl Feeder, Two Way Conveyor, Extended Pallet Table)

In addition to the standard loading system that Rollomatic has proposed for over 3 decades, we offer additional peripherals for extended unattended production time, custom part handling, or other customer needs.

Custom Applications (Pliers, Inserts – LaserSmart & GrindSmart, Extra Long Parts)

We also have the ability to offer custom solutions to accommodate different or irregular shaped parts. Our team of Applications Engineers provide the ingenuity & expertise to solve your loading challenges.