Our vision of “Smart Autonomous Grinding” is to provide Rollomatic machine users with a fully autonomous machine capable of managing the production by itself with very little human intervention. A part of this ambitious project is the ability of the machine to manage the offsets to get the first parts within specification. Further items include to be able to achieve unattended production over several days within very tight tolerances an to interact with external robotic and automation systems. The Smart Autonomous Grinding program also includes machine connectivity and communication exchange systems with other equipment such as measuring machines, laser etching, etc.

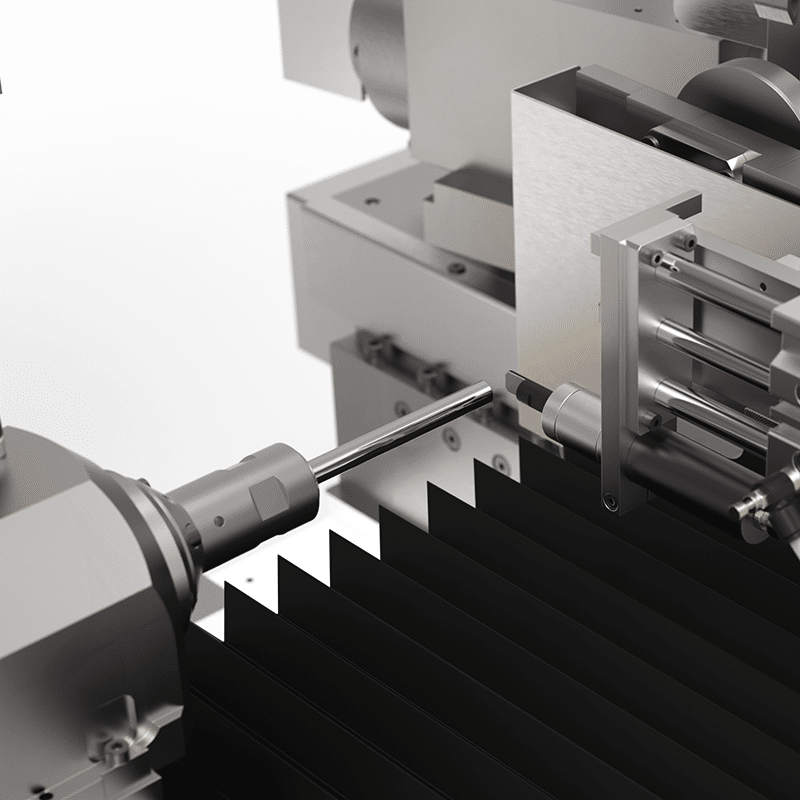

The ShapeSmart® precision pinch & peel grinding machines are based on the proven method of pinch grinding, a technology invented by Rollomatic, that ensures polished surface finishes and unmatched performances achieving micron precision. There are two grinding methods, the first one consists of peeling the part in a single pass with simultaneous engagement of a roughing and finishing wheel. For large material removals, the second process is a series of roughing passes followed by a final roughing/finishing pass. This reduces wear on the roughing wheel and still provides excellent accuracy and minimal run-out.