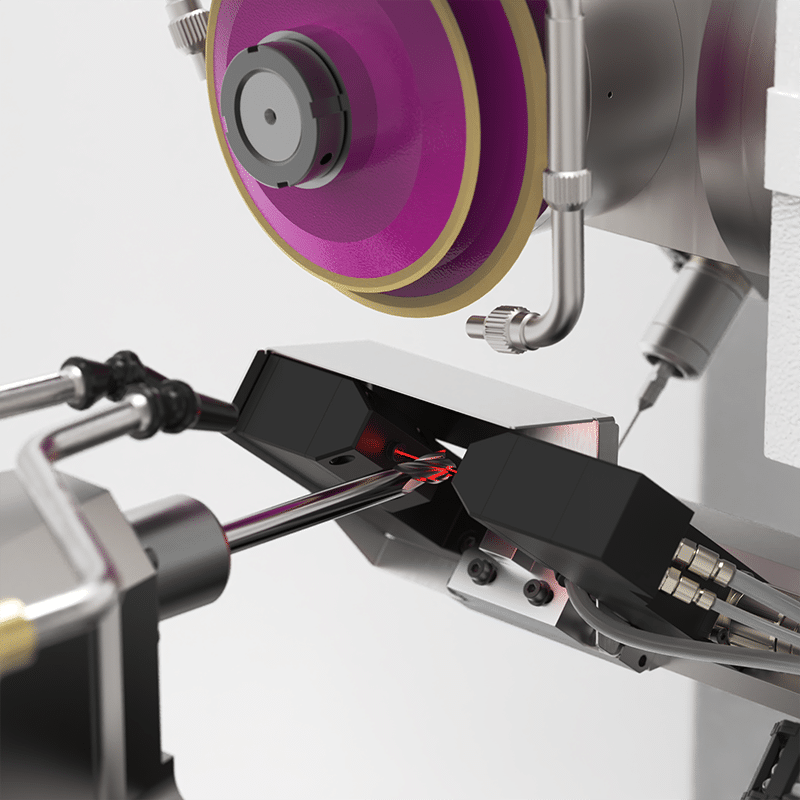

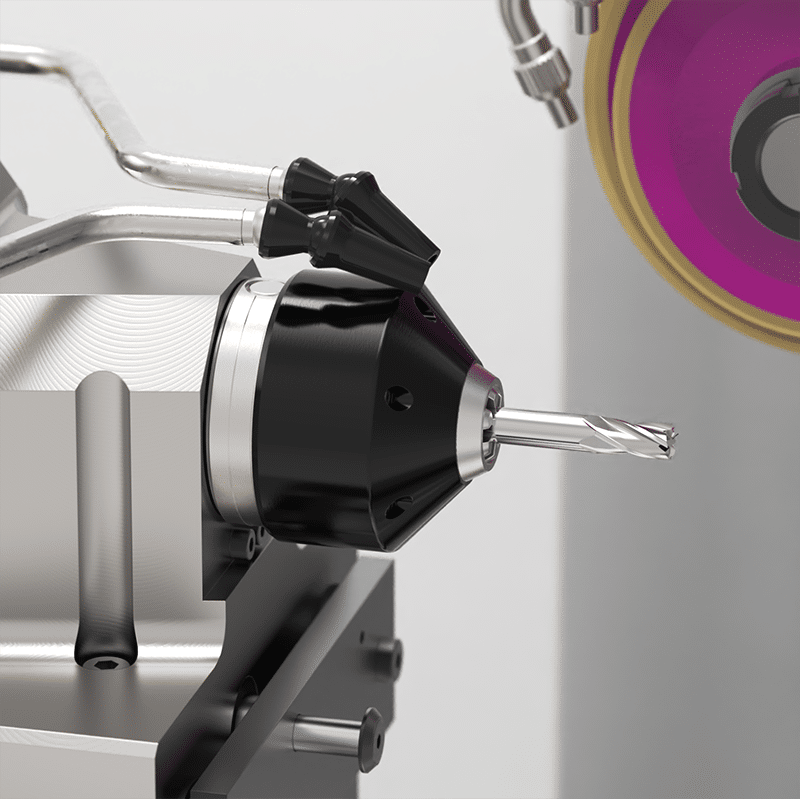

The 5-axis precision tool grinder GrindSmart®530XS has been designed for manufacturing high performance rotary cutting tools in both long and short batches covering a wide range of diameter from Ø. 0.1 to 20.0 mm (.004″ – .75″).

This machine is equipped with linear motors, combined with the torque motor on the rotary axis, provides more benefits such as enhanced surface finish and reduced maintenance costs. The oil used for cooling and lubricating the linear motors is the same as the coolant oil. This ensures consistent thermal stability during setup and production without incurring additional energy consumption.