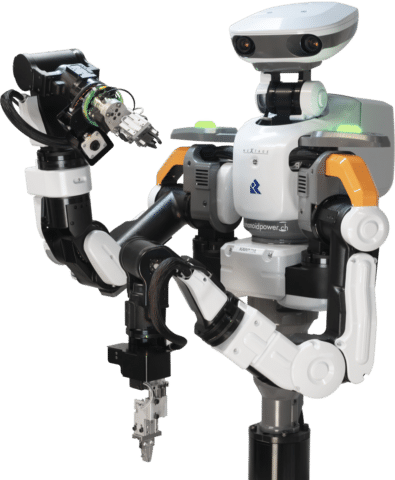

NEXTAGE NXA

Dual-Arm Industrial Robot

NEXTAGE liberates human beings from menial repetitive labor, allowing them to focus on areas that require creativity and generate added value, such as process management and improvement activities.

NEXTAGE is a new type of industrial robot that can perform tasks in location that are difficult for traditional robots. With its human-like kinematics, NEXTAGE can easily take the place of people and utilize its two arms to take over that tedious job without the need for users to redesign the production line and without specialized robot tools.

Users can control and teach NEXTAGE what to do with a graphical user interface that can conveniently be handled by people without programming skills. The four video cameras (two on the head and one on each arm) offer an advantage to conduct various tasks that are challenging for traditional industrial robots. Accuracy is 0.5 mm by utilizing the cameras, while position repeatability is 0.03 mm.

Hundreds of NEXTAGE are currently working in factories, some 24h/7days.

NEXTAGE coexists with human beings, at the same time it collaborates with conventional industrial robots and specialized equipment.

Industrial robots are now in the next phase of their evolution, from mere “equipment” to becoming a “partner”.

FEATURES

Head cameras

Both cameras are fixed on the head and allow the robot a global vision, detecting any change in the working environment to adapt itself without realignment. These life-like eyes allow it to respond instantly to the demands of the production line or to automatically perform simple tasks. The robot can also assess 3D coordinates determined by positioned origins allowing it to maneuver easily under changing light conditions.

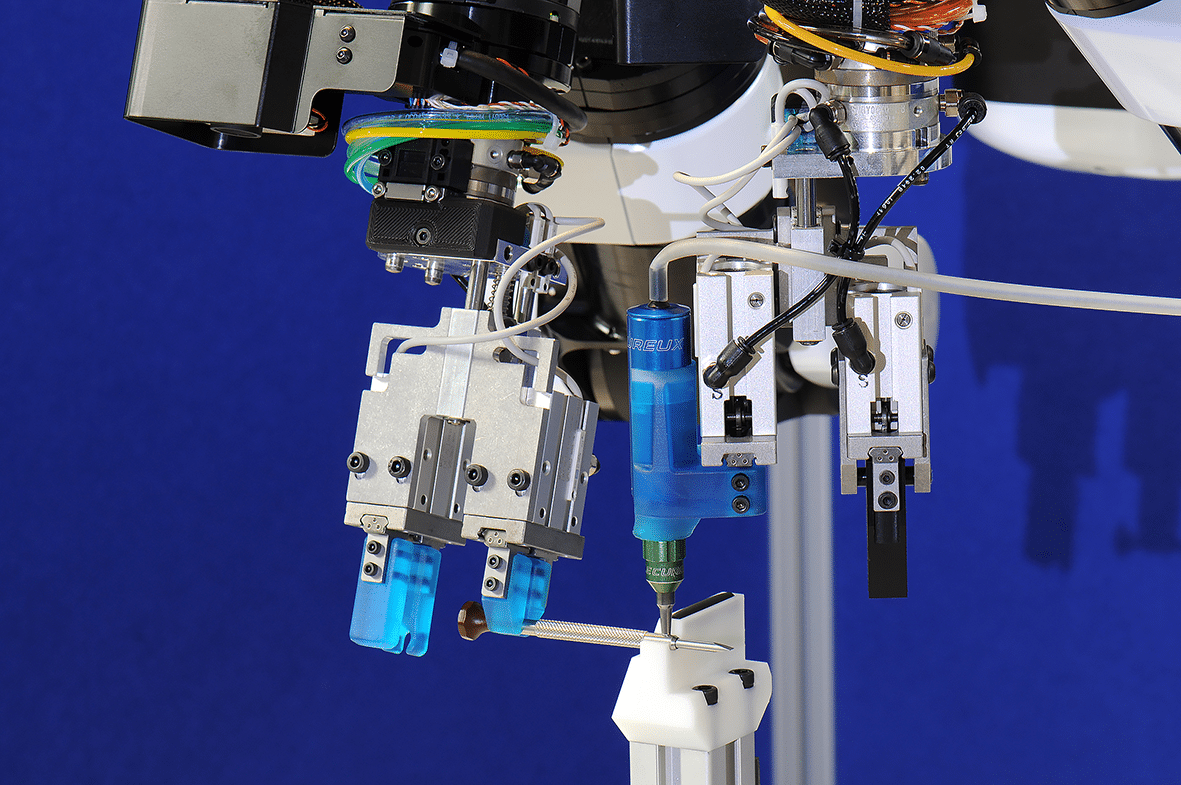

Hand cameras

These two hand cameras perform a three-dimensional capture of the object using the entire stroke of the arms.

Grippers and their supports

Specific grippers are developed and manufactured by the Rollomatic HumanoidPower division according to your specific application, regardless of the number of operations. NEXTAGE® is able to change and store its grippers itself as needed.

Secure design

The 15 axes consist of low power motors, maximum 80 watts. Easily visible LEDs on the shoulders indicate the status of the NEXTAGE® robot.